Why “Day Zero”? The American Typefounding Fellowship conference proper started on Friday, August 24th, but the day before that had technical sessions, where we got to see how M&H Type run their Monotype Composition casters. I attended the afternoon session, not so much to learn how to run a caster, but to see the special quirks that every foundry seems to have on how they run their casters. As an aside, there was also a “Day -1” which consisted of an evening hospitality suite at our hotel.

But before the afternoon tech session, I spent the morning on my own walking tour of San Francisco. I started at the CalTrain station (having taken the train from our hotel in South San Francisco) and headed west. Despite all the hills, the city planners doggedly designed a grid street pattern, resulting in streets that were straight in one horizontal dimension, but anything but in the vertical. The hills made for good exercise walking though.

On a recommendation from Brian Ferrett (one of our M&H Type hosts) I visited the Cable Car Museum. There you can see the machinery which still runs the four remaining cable car lines, along with some displays explaining the history and operation of the system.

On a recommendation from Brian Ferrett (one of our M&H Type hosts) I visited the Cable Car Museum. There you can see the machinery which still runs the four remaining cable car lines, along with some displays explaining the history and operation of the system.

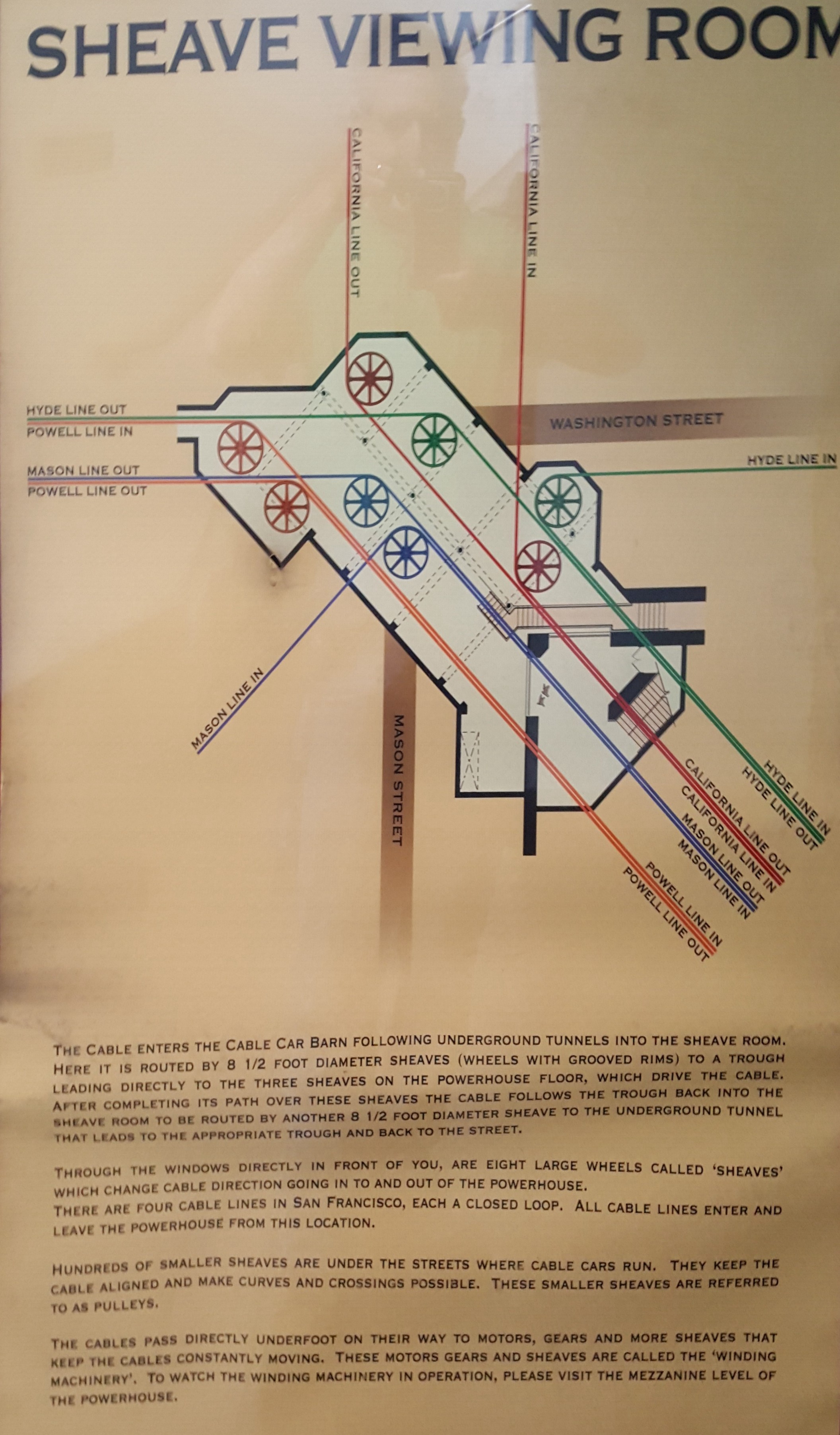

Downstairs is the Sheave Viewing Room where you can see the 8-and-a-half-foot diameter sheaves (cable pulleys) at odd angles which guide the cable loops each into their own track directions. Other similar sheaves exist under the roadway at the line terminus and wherever the line turns a corner.

Downstairs is the Sheave Viewing Room where you can see the 8-and-a-half-foot diameter sheaves (cable pulleys) at odd angles which guide the cable loops each into their own track directions. Other similar sheaves exist under the roadway at the line terminus and wherever the line turns a corner.

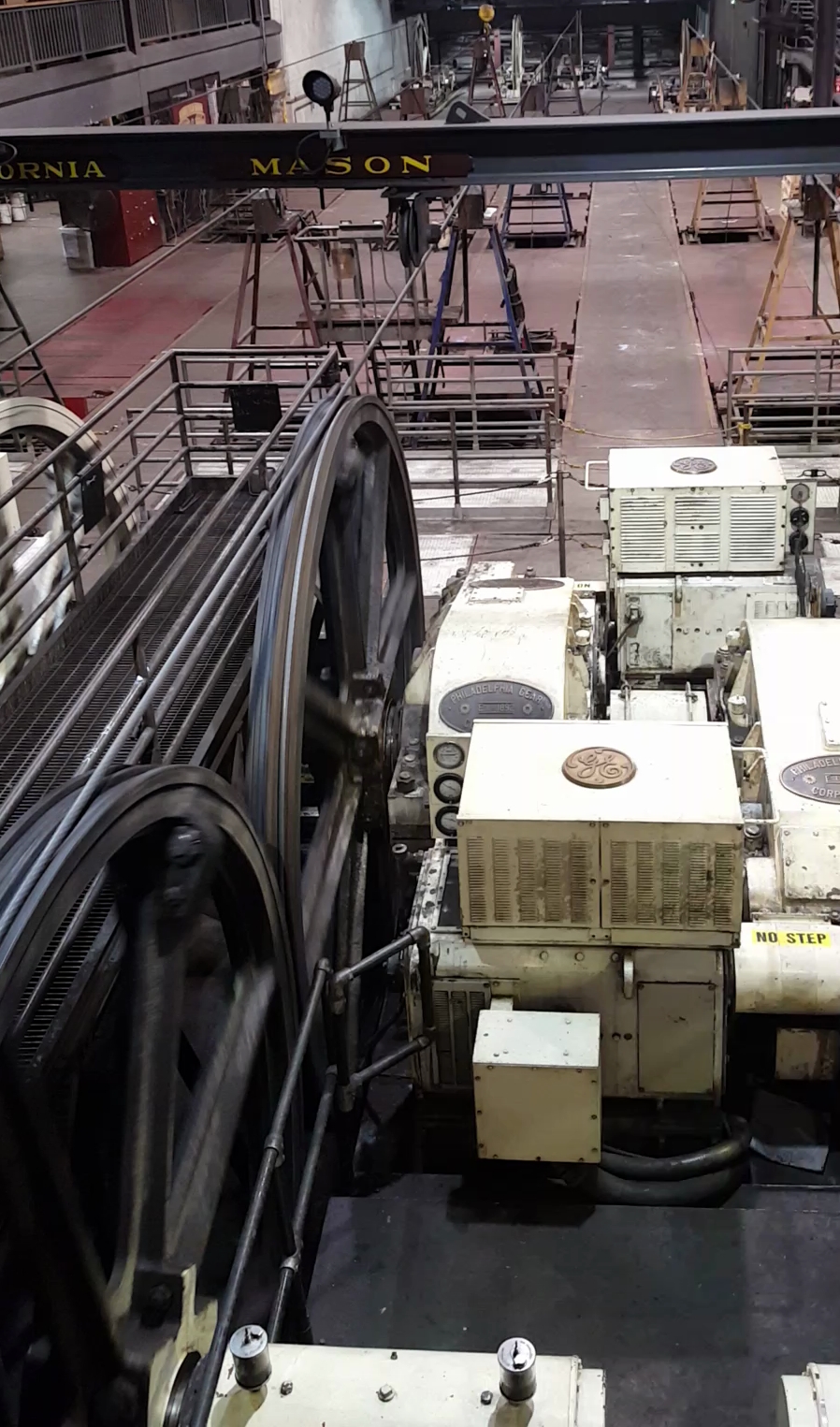

Upstairs is a mezzanine which contains the museum exhibits and overlooks the maintenance machine shop and the winding equipment that pulls the cable loops along. Each cable loop has one sheave driven by a geared-down electric motor, an idler sheave to make the cable wrap further around the drive sheave (to reduce slippage), and a third sheave on a long track which maintains tension on the loop.

From the museum I continued my walking tour, including walking up that famous block of Lombard Street. By then it was getting near time for the afternoon technical session (and my phone/GPS battery was running out of juice) so I took a city bus to the Presidio, where Arion Press and M&H Type are located. After a couple sandwiches for lunch I joined the tech session in M&H’s casting room.

Along one wall, they have 5 Monotype Composition casters and a remelt furnace. Along the other wall are a Giant caster, a Supercaster, a Material Maker, and several Thompsons. A row of cabinets separates the two aisles.

Brian was demonstrating one of their Monotype composition casters driven by Bill Welliver’s computer interface, and John Cornelisse was installing his computer interface for demonstration on one of the other composition casters. Off to the side there was the paper tower from another caster with an old Monroe Postman computer interface.

One of their local quirks is that they place a shim next to the left side of the mould when they install it on the caster, shifting the mould a bit (0.020″ maybe—I forgot to ask) to the right. Brian doesn’t know why they do this, other than because they’ve always done this. Evidently in the dim past someone determined that a shim there solved some problem (and didn’t create another) and it is now standard operating procedure.

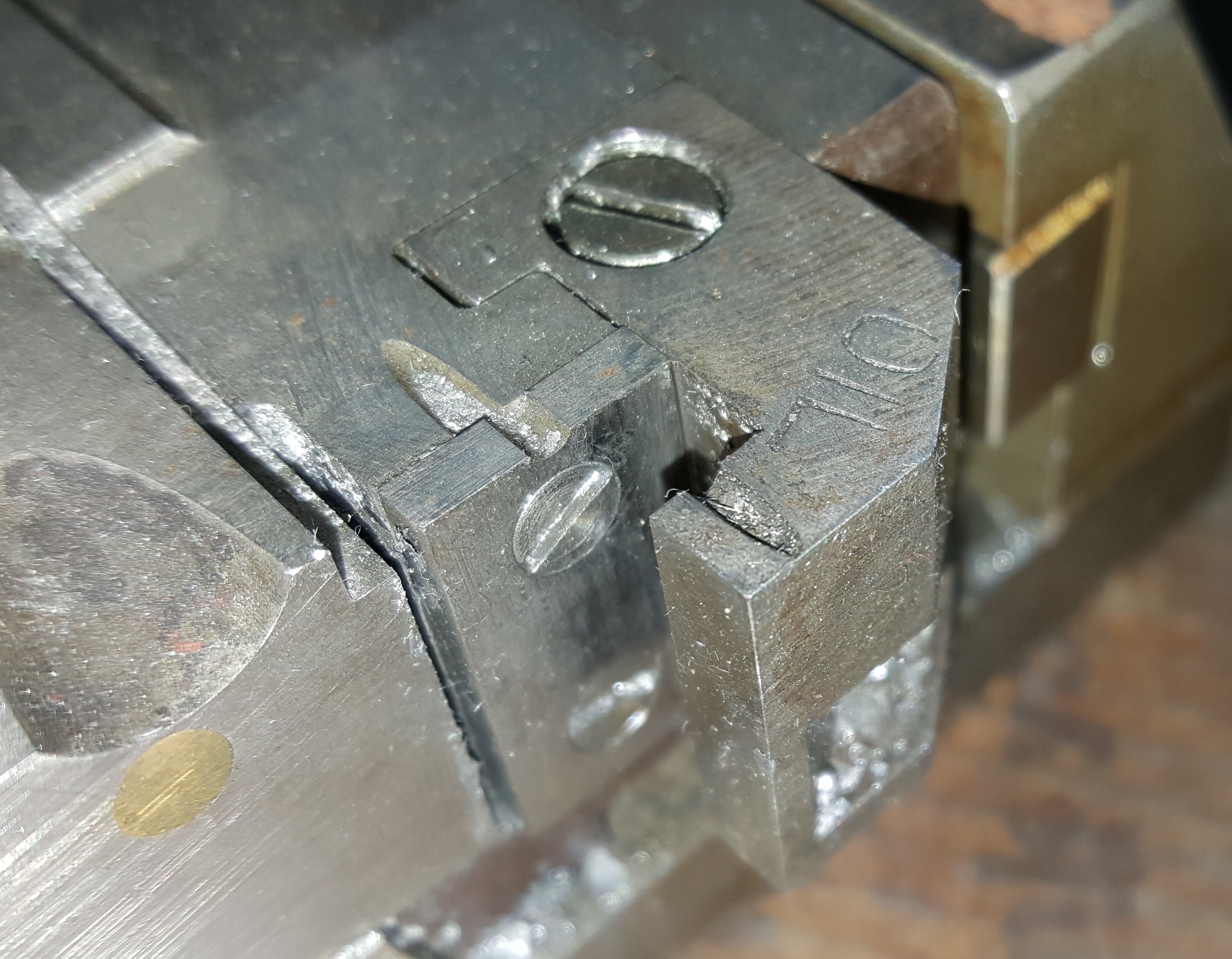

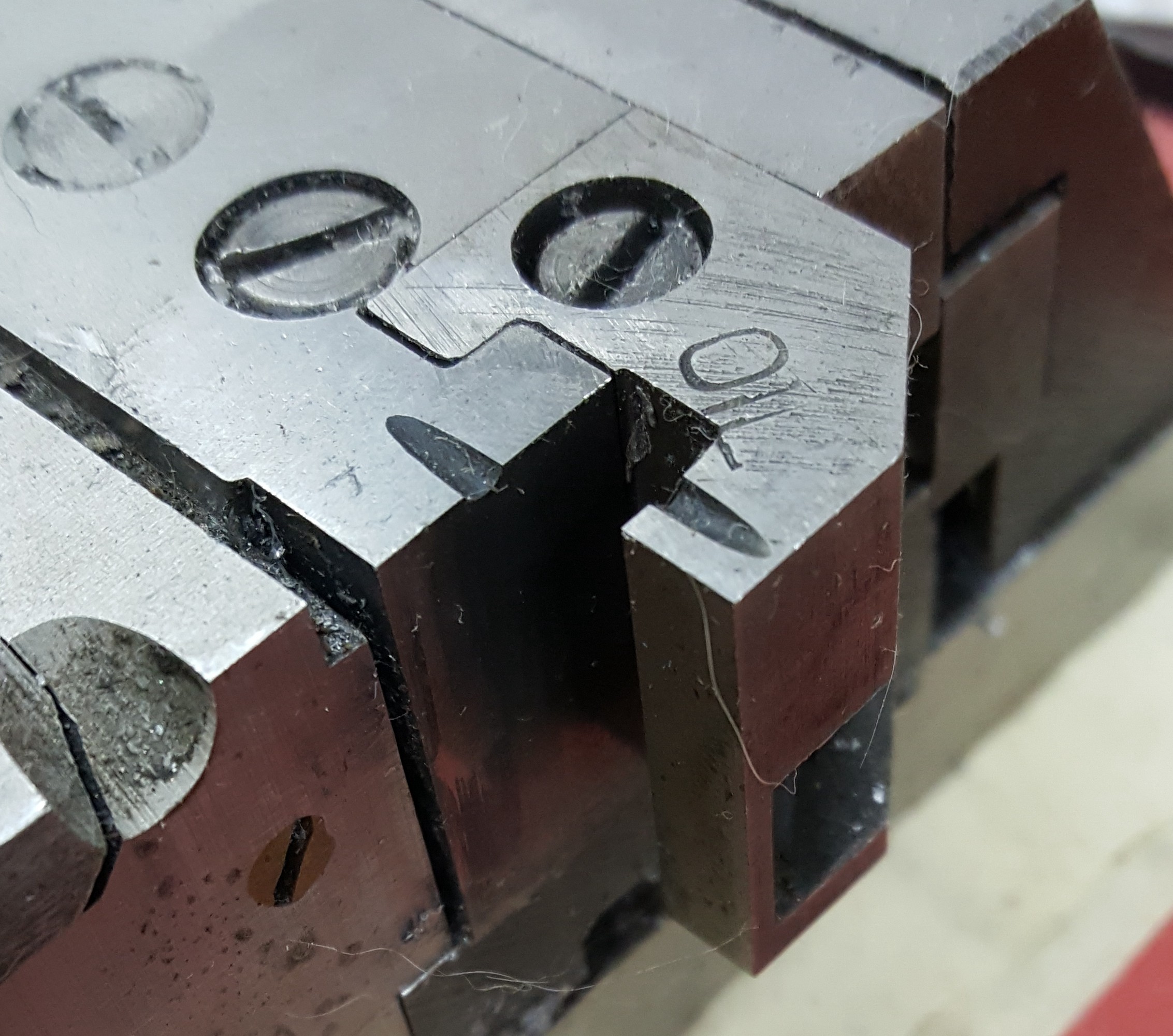

Another item I have not seen before is the extended mould coupling hook on their large composition moulds. Normally for large composition work, a special mould coupling hook is used which shifts the crossblock about 12 points to the right (more precisely, it allows the type carrier to be 12 points to the left while the crossblock is in its proper casting position). This special hook is extended 12 points, and part of it forms a 12-point spacer between the end of the type carrier and the mould crossblock. M&H’s large comp moulds, however, have a separate extended hook and spacer, each attached independently to the crossblock.

The unusual hook is extended by 12 points but the spacer which is normally part of it is instead a separate piece with two screws holding it.

The part code for the standard coupling hook seems to be 1MB3E2, at least for the 3E mould shown on pages 38/39 of Lanston’s Plate Book; it comes as part of every mould and may have different part codes for each mould it is supplied with. The extended coupling hook has part code 50B1 shown on Plate 35 of the English Spare Parts List.

After the tech session, some attendees took the opportunity to visit the Letterform Archive, a collection of over 50,000 items relating to lettering, calligraphy, and typography.

Looking back over half of the main room at The Box. The other half is under the mezzanine to the left, and there are two small and even more packed rooms at the front (below me).

After dinner on our own, we met for the evening at The Box, a shop selling all manner of printing-related ephemera and equipment. Matchbooks, boxed games, a John Bull printing set, medicine boxes and bottle labels, old rubber stamps, a sign press, biscuit tins, record sleeves and labels, playing cards, show posters, sheet music, and the list goes on. They also have several old presses scattered throughout the room.

One small rotating rack (in the foreground of the photo) contained illustrations of perhaps 80 different old presses and related equipment. The cuts these had been printed from were probably used in some equipment catalogues, and they were generally only marked with a number (probably an illustration number), but you could often read the brand of the press from the illustration itself.

They also had original outline drawings of letters from several typefaces (and apparently many more in storage) which would have been used to make the templates for matrix or punch cutting.

Just that evening, there was a truck parked at their loading door with a Rogers Typograph on it waiting to be unloaded. This machine was an early attempt at automated line casting. In use, each wire would have several matrices for one letter. Pressing a key would drop one mat down its wire, where it would stack against all the other mats in the line. After casting the line, the entire basket of wires would tip back, and the mats would each slide back to its proper storage spot via its wire.

At the end of the evening, I traded my navigation abilities for a ride back to our hotel in the car Rich Hopkins had rented.

Leave a Reply