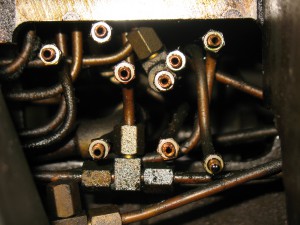

In my next task of getting the paper tower operational on my Monotype composition caster, I have started cleaning and lubricating the various pneumatic control valves. The first one I did is a combination of the Unit Shift control valve and a manifold for the Quadding and Centering unit, located on the left table apron below the paper tower. After removing the valve body and its mounting plate I was left with a mess of pipe connections:

Unfortunately the pipes have some spring to them and shifted out of position once the valve base was removed. Removing this base required a specially modified cabinet-tip screwdriver to remove the retaining nuts for the pipes.

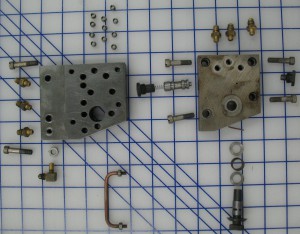

I disassembled the valve and base and cleaned all the parts with solvent and a brush:

Those little rings near the upper left are the retaining nuts for the pipes. I reassembled the valve using a light oil, and got to work on reinstalling the base plate. This job was made difficult by the shifted positions of the pipes as there is not enough room to reach behind the plate and put them in their holes individually. Furthermore, the mould blade cam lever prevents the plate from dropping into place from more than about an inch away. I put short lengths of wire into each pipe, which allowed me to guide each into its own hole. Inn retrospect though I should have chosen wire that was a closer fit to the inside diameter of the pipe, and also stiffer than the soft iron stove wire I actually used. This would have made it easier to coax each pipe into its proper hole just by shifting the wire.

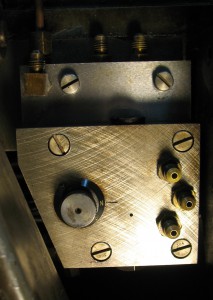

This shows the base plate in position with some of the pipes secured, and others with the positioning wires still in place. This photo and the next were lit by my work light which was below the valve area, hence the spooky upside-down shadowing. Once I had all the pipes secured I could re-mount the valve body; I cleaned the mating surfaces, applied a heavy oil, and screwed the valve onto the mounting plate.

The control knob now moves freely allowing Unit Shift to be turned on and off easily. The other buffer valve, which connects to the three flare fittings on the front, still remains to be installed.

The next valve and base plate I will clean is the one for Unit Adding, which is not installed on my caster, so instead of the valve there is a dummy plate mounted on the base plate which routes all the air lines as if Unit Adding were turned off.

Leave a Reply