The Monotype caster has a part called a fence which separates the accumulating line of type from previous lines already pushed onto the galley. This fence has a guide pin at the rear end which fits into a hole in the right type channel block to keep the fence in position as it is raised and lowered as part of the sequence of motions that push a completed line of type onto the galley.

Normally this pin gets pretty light duty, but it can be broken if the matcase is improperly inserted into the caster and the ribbon calls for casting a matrix in the first (NI) column and one of the near-bottom rows (14 or 15). The matrix positioning mechanism will push the matcase into this pin, shearing it off and bending the rule. Generally the caster jams and stalls at that point, and getting it unjammed can be quite a job. Once things are unjammed, the fence can be replaced and you can get on with casting, this time with the matcase properly engaged in the positioning lugs.

The fence itself is generally springy enough to recover its straightness, unless too much force was applies while trying to unjam things. Even if it remains slightly bowed, it can be straightened. The problem is replacing the guide pin, a part not readily available. The stub of the broken pin will will remain on the end of the fence, held in place by two small rivets, whose heads have been ground down flush making them quite hard to spot. These rivets can be drilled out, preferably from the back side so only the broken stub of the pin and not the fence itself is damaged if the drill wanders off course a bit. The holes in the fence are tapered and drilling into them could lose most of the taper.

I had a broken fence at this stage, with the pin stub and rivets removed, which I found while helping Rich Hopkins clean out his shed a bit when I was visiting in May. I decided to repair it to see how much trouble it would be.

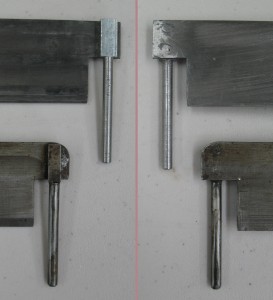

I made the replacement pin in a single piece, with a couple of projecting pegs instead of separate rivets. I started with a length of ¼″ square keystock, and used the lathe to turn the round pin, keeping some of the original square shape to form a head that would attach to the fence. I turned the pin off center in the keystock so all of the excess metal in the head would be on one side of the pin. I also used the lathe to cut both the pin and the head to the correct length. Then I clamped the part in the vise on my mill, and used a CNC milling program to cut away most of the excess metal on the head, leaving two pegs in the correct positions to match the rivet holes in the fence. A bit of a miscue on the height of the part meant that I also milled a thin shaving off the top of my milling vise.

As it turned out the pegs didn’t quite have the right spacing between them and would not both fit together into the holes on the fence. I used a small file on one of the pegs to reduce its diameter on one side until they fit into the fence and the head of the pin seated fully against the fence. Then I placed the end of the fence on an anvil and use the ball side of a ball-pein hammer to flatten down the pegs, forming rivet heads in the tapered holes of the fence. I filed the excess rivet heads off until they were flush with the surface of the fence, so that type would not snag or get damaged as it slides by this point on the fence.

Altogether the repair looks good and feels solid. Once I do this on a couple more fences I should have the peg spacing adjusted properly so no filing is required. Then I can make several of these pins available for other caster owners who need their fences mended.

This part that I have been calling the “fence” is actually properly called the Rule (symbol 39F) and the broken part is the Rule Guide Pin c39F1. Uncharacteristically, the rivets that hold the pin to the rule do not appear to have part symbols.