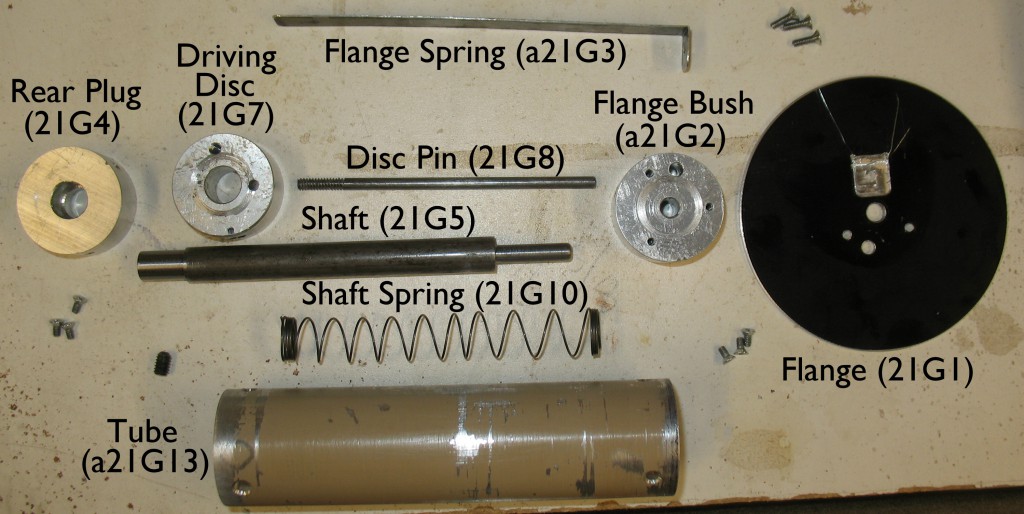

I made myself a Winding Spool for my Monotype caster, to take up the ribbon as the machine reads it. The internal mechanism is similar but not identical to the standard part. The main difference is that the part know as the Driving Disc 21G7 is closer to the rear of the machine (the open end of the spool) and also does the duty of the Shaft Spring Abutment 21G11, with the spring being held between the Driving Disc and the front end cap (Flange Bush a21G2). The Driving Disc is held in place on the Shaft by a setscrew, and the Shaft Driving Disc Pin 21G8 is threaded directly into the Driving Disc and held by thread locking compound rather than a locknut.

The parts for my home-made Winding Spool, showing the names and numbers of the closest corresponding standard parts.

Most of the parts were scavenged. The Tube was a piece from the photosensitive drum of an old laser toner cartridge, the Flange Spring was a strip cut off some scrap aluminum siding, and the Flange came from some random piece of black anodized aluminum scrap. The spring was hand wound on my lathe. Everything is held together with #2-56 flat head screws in countersunk holes. Getting the spool to work properly required a bit of fine tuning on the lathe adjusting the thickness of the Rear Plug and Flange Bush so the Shaft had the correct range of longitudinal motion.

When the spool is off the caster both ends of the Shaft are flush with the ends of the spool. Once on the caster, the big end of the shaft is pushed by the Winding Spool Spring Box Plunger group X25G, causing the small end to project and engage the hole in the center of the drive disk. If the Button 25G2 is turned so its bumps are not in the notches in its housing, this is all that happens, and the spool can rotate freely. If the button is turned so its bumps are in the housing notches, the Shaft is pushed further, causing the Disc Pin to also project from the end of the spool and engage one of the drive holes on the drive disk. In this manner the Winding Spool Driving Ratchet X23G can turn the spool to apply enough tension to the ribbon to cause it to wind onto the spool.

With this spool on the caster, my patched-up ribbon runs flawlessly from start to finish, although I have yet to try this with the air on to see how much leakage there is over the ribbon patches.

I think I’m finally coming to the home stretch to get this sucker working. All that seems to be left is to clean the mould so it operates smoothly and verify that my closed-loop cooling system still works, and then I’m ready to try casting this ribbon.

Leave a Reply