After much thought about my problem with second shot, and with little help from any manuals, I’ve got my caster to behave properly.

The second shot problem was caused by an incorrect adjustment in the pump crosshead and linkage area. The pair of levers that operate the pump have a slotted hole and spring plunger in the link that joins them. When the pump is not in use, this plunger is supposed to be compressed a tiny bit, and it ensures that the pump piston is firmly held at the top of its stroke. The plunger also compresses if the pump piston jams in the down position; very old casters did not have the slot, so a jammed pump would either stall the caster or break something.

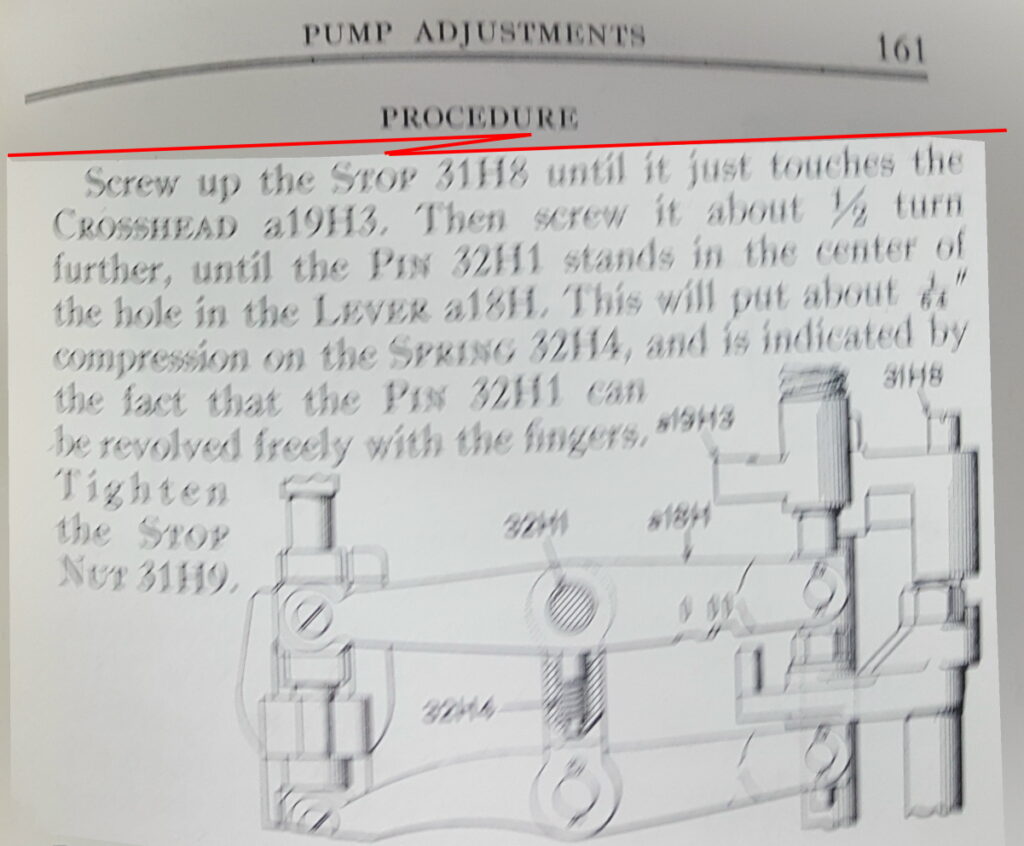

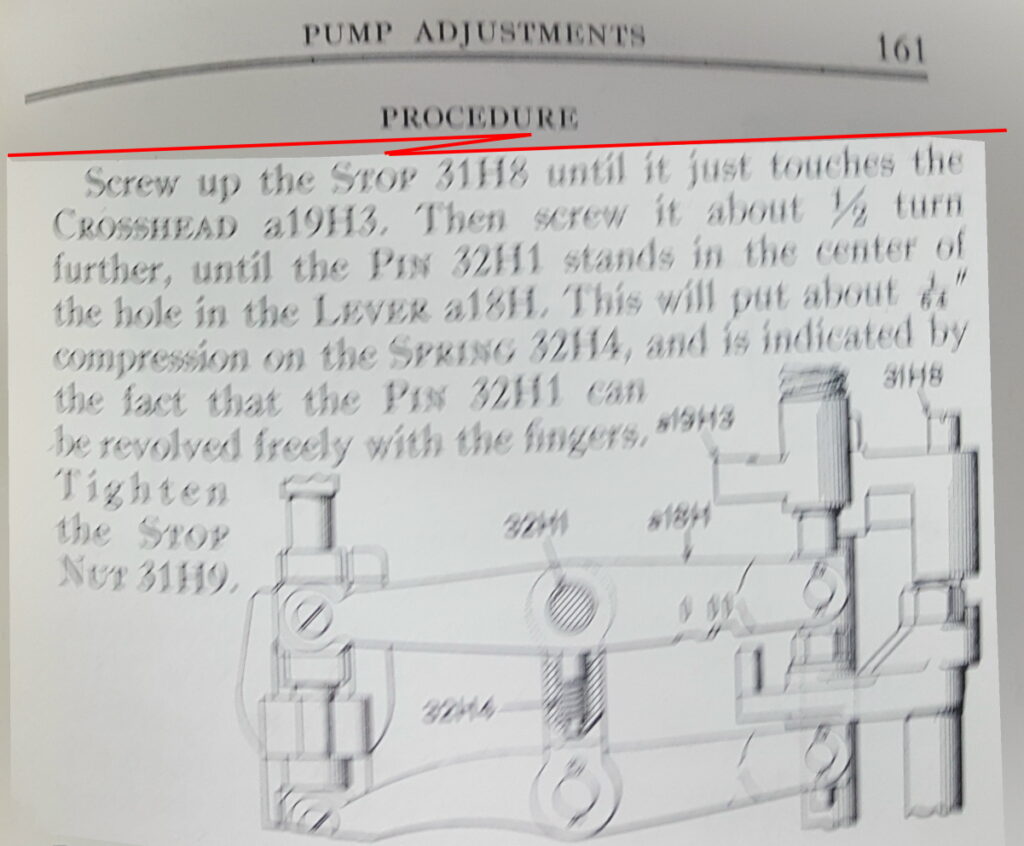

The adjustment is described in Casting Machine Adjustments, on page 161 in the copy I consulted: Note that the reference to the pin 32H1 being in the center of the hole in the lever refers to the older casters; in newer casters like mine this hole is a slot in the lever and all that is necessary is the 1/64″ clearance produced by a half turn of the adjusting screw.

Note that the reference to the pin 32H1 being in the center of the hole in the lever refers to the older casters; in newer casters like mine this hole is a slot in the lever and all that is necessary is the 1/64″ clearance produced by a half turn of the adjusting screw.

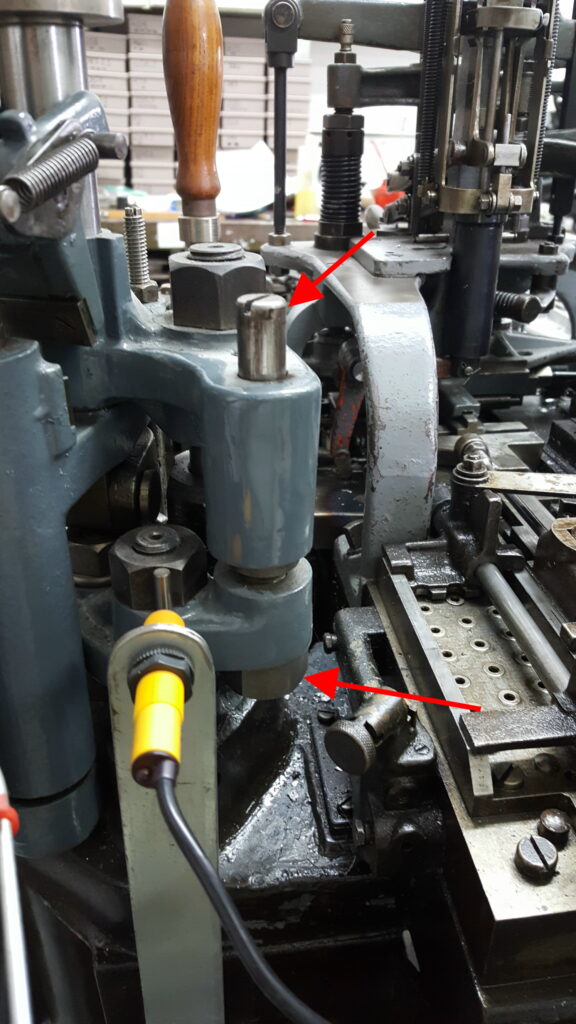

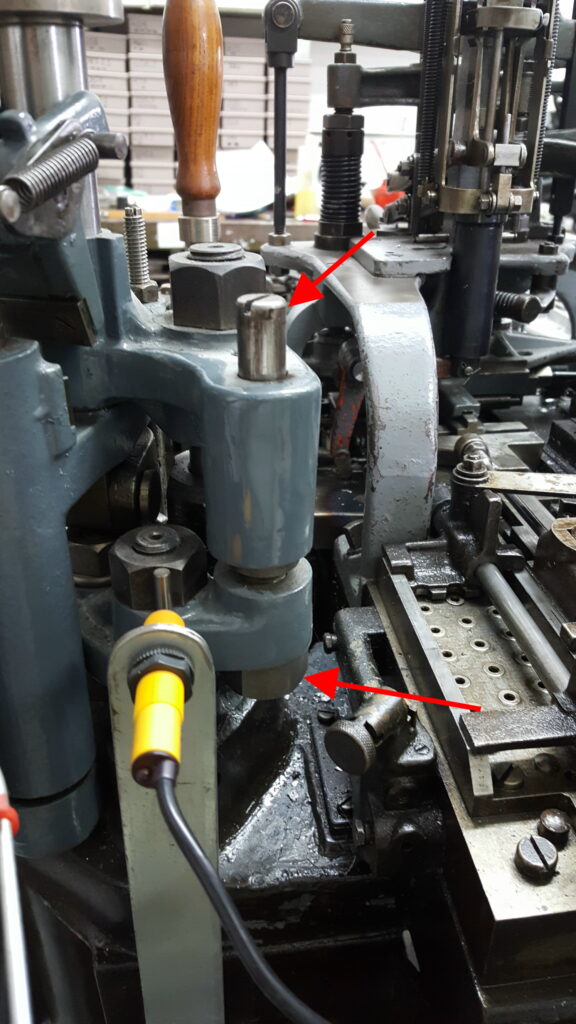

Here is the adjustment on my caster, as seen from the rear:

Upper arrow is the adjustment screw 31H8, lower arrow is the locknut 31H9. The yellow thing is a sensor for my pump stroke counter.

On my caster, there was no overthrow in the adjustment, and the pivot pin in the linkage had a bit of drag but was not fully loose, and that was enough to allow a bit of a squirt as the pump descended after casting.

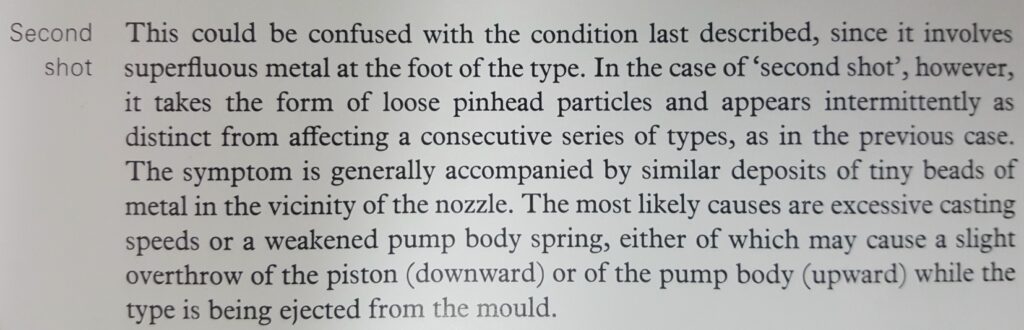

The frustrating part of this episode was that the two manuals that described the “second shot” problem never mentioned to check this adjustment. They just contained vague explanations about spring pressures being wrong with no hints as to how to check or adjust them:

From the ‘Monotype’ Composition Caster Manual. A very similar explanation exists in The Monotype Casting Machine Manual.

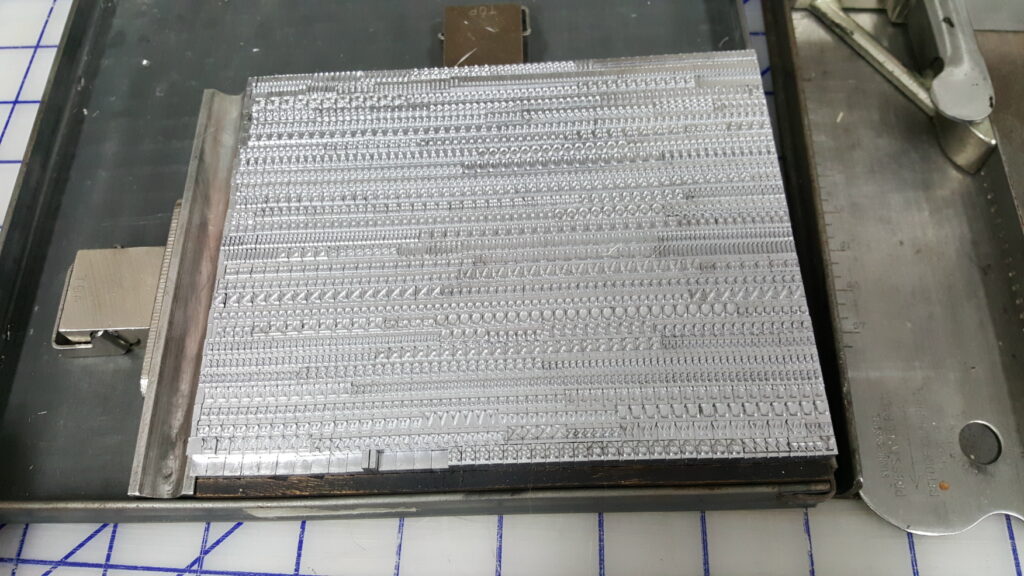

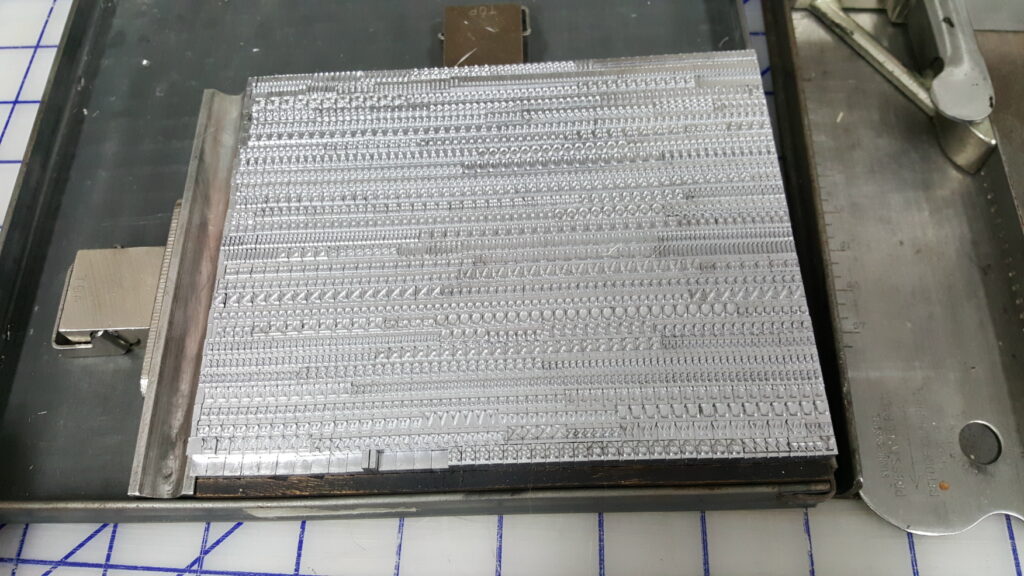

With this problem tackled, and a new type clamp installed in the type carrier, I got a good font cast: The run was still not problem-free, but the remaining issues did not disturb the lines of type. The remaining problems were:

The run was still not problem-free, but the remaining issues did not disturb the lines of type. The remaining problems were:

- The first type in the line would occasionally fall over in the type channel if it was very narrow (e.g. ‘i’ or ‘l’). This letter would then fall out of the channel altogether, but for font casting missing one lowercase letter is not important, and it also did not leave a significantly shorter line. I thought the type channel had a ridge which engaged the nick of the type, which should prevent this; this is something else to look into.

- On one occasion, the galley cycle was missed; I had to stop the run, remove the extra types that should have been on the next line, and rewind the computer interface to the start of the line. The galley trip is a touchy adjustment; if set too sensitive it will trip during a single justification cycle (which it should not), and the sensitivity depends somewhat on the caster speed.

- During the galley cycle, the rule would sometimes snag on the type in the channel and lift it up as it rose; the type would drop down again each time before the column pusher moved in onto the galley, but there is definitely a chance this might derange the type. This might be due to a slight curve in the rule causing it to press the type against the column pusher a bit.

- I still have a bit of a temperature control problem: Keeping the casting running cool enough for larger type meant that the nozzle could freeze when casting a long run of narrow characters. I got around this by shutting off the mould cooling water while a long run of narrow characters was casting. This is only an issue for font casting; in true composition casting one does not encounter long runs of i’s and l’s! A very distant possibility in the future would be to have the computer interface automatically control the motor speed control of the VFD to vary the motor speed based on a running average of the widths of the type being cast.