The Quadding and Centering system on the Monotype composition caster is controlled by two actuators on the paper tower.

The one for Quadding is a simple piston inside the tower housing which causes the motion of the paper tower cam to rotate a notched counting wheel; only when the counting wheel has advanced 5 (or 10) positions (to the next notch) is the paper ribbon allowed to advance. As a result the character coded on the ribbon is repeated 5 (or 10) times. The choice of 5 or 10 is controlled by rotating part of the notched counter wheel, thus closing up half its notches.

The one for Centering is a rocker arm outside the tower housing which is tilted one way to initiate centering by preventing paper ribbon advance, and is tilted back to its normal position when a sensor on the galley detects that the line is full. It is also forced to its normal position when both Quadding and Centering are coded on the same ribbon line (which IMHO is a keyboarding error).

Both of these receive their pneumatic signals via a manifold in the mounting plate of the Unit Shift valve, and these control signals originate in another valve (to be detailed later) mounted on the rear apron of the caster table.

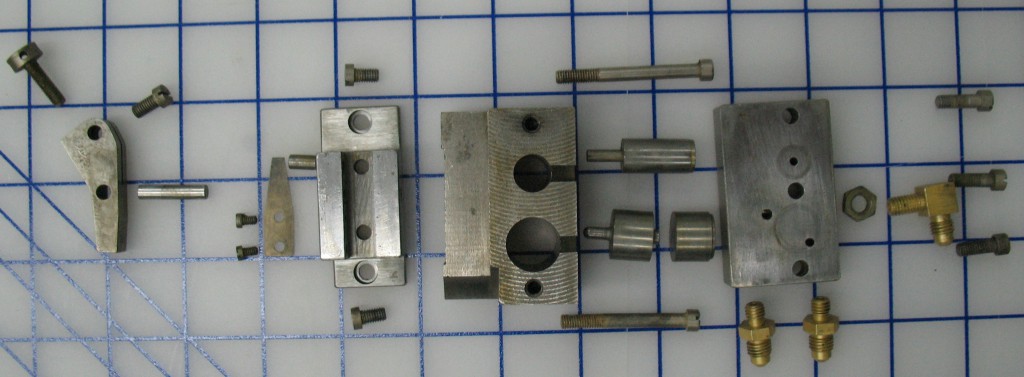

The Centering actuator contains quite a few parts with a bit of clever pneumatics involved:

The clever part is the reset piston (which returns the rocker arm to its normal position). Firstly, it is a double piston, so it can either be actuated by the line-full signal from the galley or by the redundant selection of both Quadding and Centering on the same ribbon position. Each of these signals has its own isolated cavity in the cylinder, and either one will raise the upper piston and push the rocker arm to its normal position. Secondly, by using a larger diameter piston for the reset piston, the air pressure that rocks the arm when starting centering is able to be overcome by the reset piston actuated by the same pressure.

It should be noted that the two mounting screws (the long ones above and below the pistons) are not the same length (and are shown in the wrong positions in the above photo). The longer screw penetrates into the inside of the paper tower housing and acts as a mounting screw for the Quadding actuator as well.

The centering actuator was reassembled and installed on the side of the paper tower facing the operator just below the notched Quadding counting wheel:

The second photo is taken looking obliquely downward between the paper tower and the centering pin arm from the left side of the machine.

The Quadding actuator is installed inside the paper tower and all the air lines connect to the manifold in the Unit Shift Valve mounting plate:

The Centering actuator is also visible in the first photo.

The next pneumatic parts to clean are the dummy valve and mounting plate for Unit Adding, and I might also correct the messy repair job on one of the related air lines.