After finishing one side of the extended-stroke piston rod for my Monotype, I took apart all the work holders and gave the mill a bit of a cleaning.

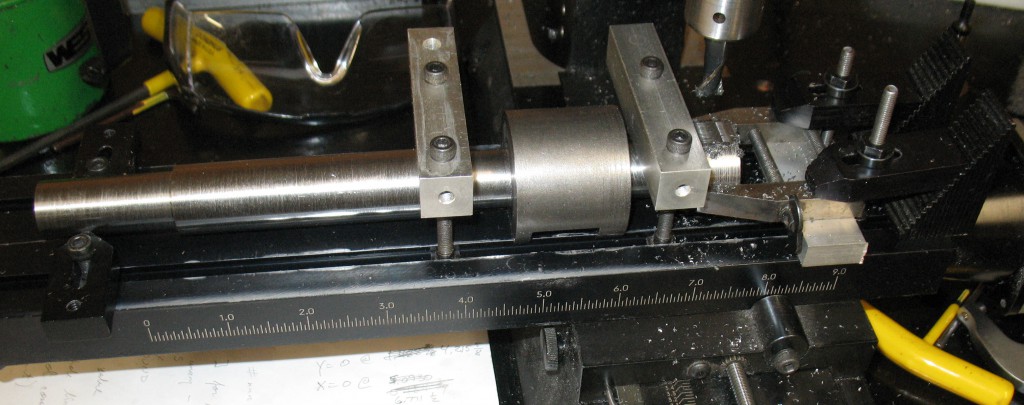

The rod has now been clamped down to the milling table with the first side down and the rod axis parallel to the mill X axis.

The only contact between the piston rod and milling table are the two flat spots at either end of the large-diameter area. The two square aluminum bars hold it down and prevent it from moving left-to-right, but the small contact area between the rod and the table made it difficult to stop the rod from turning about a vertical axis. To prevent this I added two hold-downs acting only as cleats at the far left end, and on the right end, used a machinist’s clamp tightened onto the piston rod and itself clamped to the milling table using a spacer and hold-downs.

When the picture was taken I had already done a few test passes cutting the flat on the top of the rod, to make sure I had all my coordinate origins correct and also that I had properly reversed the X and Y axes of the traversal path so it now does long Y traverses with successive small X stepovers.

Leave a Reply